|

UK Koi Policy Unit

www.ukkpu.co.uk

|

|

|

|

|

|

|

|

|

|

|

|

|

Friction Loss

By

Syd Mitchell

|

|

This article was commissioned by, and first published in,

Koi Carp Magazine.

It may not be copied or reproduced in any way without

prior written permission from the Editor.

|

|

|

|

|

|

A simple explanation of friction loss and how it affects pond pipe-work design

|

|

“.......I have quite a few friends who are koi keepers and we get together quite often and talk about all things koi. One friend is building his third pond and has been told to allow for friction loss in his design. Although we’ve heard about friction loss none of us really understand what it is or why it happens......”

|

|

This question was sent in to Koi Carp magazine and it can be split into two parts:

The first part; “what is friction loss?” can be answered quite simply - it is the loss that occurs in a pipe as water flowing along it scrapes past the internal surfaces, and the effect of this loss is to reduce the flow to less than that which would otherwise be expected. In some systems that would be an over simplification, because friction losses are not just confined to water in pipes, they also occur when air is blown through ducts, or when viscous liquids like oil are pumped through pipelines. With viscous liquids, the situation becomes complicated but where water is concerned, the viscosity or “stickiness” of the liquid can be ignored, so for koi pond pipe-work, the simplification is valid.

|

|

|

Believe it or not, bricks

and planks have a lot in

common with drops of

water in pipes.....

|

|

Mind your toes!

The second part of the question; “why does it happen?” can be understood by thinking about what friction actually is and how it works. What happens to any particular drop of water as it is flowing down a pipe is difficult to imagine, but thinking about bricks sliding down planks might make it easier. Believe it or not, bricks and planks have a lot in common with drops of water in pipes. Friction affects them both in the same way but a brick is easier to watch than a particular drop of water in amongst all the other drops as they flow along a pipe, so either think about this, or try it for real. Place a brick on a plank of wood on the ground and lift one end of the plank, see figure 1. At first nothing happens, although gravity would like the brick to slide down the plank, it stays where it was put. As the end of the plank is raised further, the incline becomes steeper. Eventually gravity wins and the brick slides down. What just happened? Those who paid attention to their math teacher at school will understand, but for simplicity, let’s just agree to say that the force trying to slide the brick increased as the slope increased. At first there wasn’t enough of it to cause the brick to slide because something called friction was trying to keep it where it started, but, as the sliding force increased, the friction that was trying to hold on to the brick lost the battle and let go. Well it didn’t let go entirely, it was still trying to hold it back as best it could, which is why a brick slides slowly towards the ground rather than as quickly as if it were dropped from the same height. |

|

|

|

Some of the water flowing through a pipe is stationary!

Having understood how bricks slide down planks, it is now possible to understand how water flows through a pipe. In a gravity system for example, gravity is trying to slide each individual molecule of water along the pipe just like it did with the brick on the plank. Friction between the walls and those molecules that are actually touching the walls is trying to hold them where they are. These particular molecules are actually held stationary or are barely moving, and the next “layer” of molecules above them has to scrape past the stationary ones. These are not brought to a complete halt like the ones touching the sides, but they are slowed right down. This second “layer” slows down the third, which slows down the fourth and so on. Figure 2. shows how the “layers” of water are affected by friction. For clarity, only a few layers of molecules are shown, in practice, the number that would be affected would be huge. The total thickness of all the layers of water that are slowed down varies with the speed at which the water is trying to flow. It can vary from a tiny fraction of a millimetre up to several millimetres in thickness and the overall effect is to reduce the amount of water that would pass through the pipe if there was no friction at all.

|

|

|

|

Water flowing through pipes leading from koi ponds invariably has some silt in it. If the water moves quickly it will carry that silt all the way to its destination, but if the velocity (speed) of that water is slowed significantly, some of the silt will settle out. Over time, friction losses in bottom drain pipe-work in particular, can cause them to begin to silt up which will cause more friction losses and this will slow the water even more causing it to drop more silt. If left unchecked, the pipe could virtually silt up completely. In well managed koi ponds this will never happen because we regularly flush bottom drains and their pipe-work. Different plumbing layouts use different methods to flush bottom drains but the general principle is that there should be a sudden “whoosh” of water, stirring up any silt that has settled and washing it completely through the pipe, preferably to waste. In pipe-work, friction losses are the enemy.

But friction loss can help us

The layer of water that is either brought to a halt or very significantly slowed down is called the “boundary layer”. In a pipe, this effect is a nuisance because it means that less water can pass through it, but friction losses are not always the enemy, they can be made to work in our favour. In a vortex, water enters a cone shaped tank in such a way as to make it spin slowly up from the bottom before it can leave at the top. As it spins slowly around on its upward spiral journey (the correct expression is helical journey) towards the top, the outside layers of water in contact with the sides are also called boundary layers. They too are significantly slowed by friction losses just as in pipes. As with pipe-work, any silt being carried is also dropped and settles toward the bottom of the vortex. This effect is magnified by the boundary layer’s long slow helical journey upward and the fact that any debris it is carrying is being carried against the force of gravity.

Water won’t flow around corners

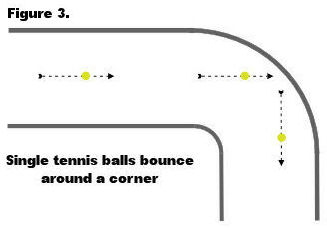

So far, where pipes are concerned, I have referred only to friction losses in straight lengths of pipe, but pipes have to turn corners and another effect that is usually quoted as a loss due to friction comes into play. Strictly, it is more like a multi car pile-up than pure friction. Instead of trying to understand those tricky little molecules and individual drops of water, it is easier to consider what happens when a tennis ball is thrown down a corridor with a radiused but sharp bend in it. The tennis ball doesn’t know that it is approaching the wall that is leading around the corner. Even if it did, it couldn’t do anything about it and float gently round the corner without touching the sides. The first the tennis ball knows about the bend is when it runs smack into the wall facing it and bounces off in a new direction. A considerable amount of energy is lost as the ball first comes to a dead stop and then starts travelling in its new direction as in figure 3. A water molecule travelling along a pipe would do exactly the same thing. It would first hit the internal walls of the bend then bounce around it. So far, where pipes are concerned, I have referred only to friction losses in straight lengths of pipe, but pipes have to turn corners and another effect that is usually quoted as a loss due to friction comes into play. Strictly, it is more like a multi car pile-up than pure friction. Instead of trying to understand those tricky little molecules and individual drops of water, it is easier to consider what happens when a tennis ball is thrown down a corridor with a radiused but sharp bend in it. The tennis ball doesn’t know that it is approaching the wall that is leading around the corner. Even if it did, it couldn’t do anything about it and float gently round the corner without touching the sides. The first the tennis ball knows about the bend is when it runs smack into the wall facing it and bounces off in a new direction. A considerable amount of energy is lost as the ball first comes to a dead stop and then starts travelling in its new direction as in figure 3. A water molecule travelling along a pipe would do exactly the same thing. It would first hit the internal walls of the bend then bounce around it. |

|

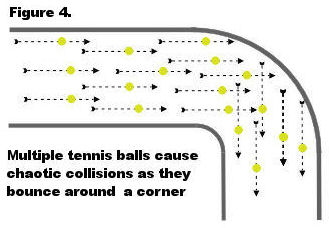

But water molecules don’t travel alone, there are countless trillions of them all doing exactly the same thing. Since tennis balls are easier to imagine, consider what would happen if instead of throwing one ball down a corridor, a huge number were thrown at the same time, see figure 4. As the first one hit the end wall and started to bounce round it, there would be others, nose to tail, running into the back of it just like a multi car pile-up. As some tried to bounce around the corner, others that were still travelling forward, would run into the side of them and bounce them into the wall a second time. Eventually all the balls would get around the bend but the paths of each individual ball would be a chaotic series of crashes and zig-zags. But water molecules don’t travel alone, there are countless trillions of them all doing exactly the same thing. Since tennis balls are easier to imagine, consider what would happen if instead of throwing one ball down a corridor, a huge number were thrown at the same time, see figure 4. As the first one hit the end wall and started to bounce round it, there would be others, nose to tail, running into the back of it just like a multi car pile-up. As some tried to bounce around the corner, others that were still travelling forward, would run into the side of them and bounce them into the wall a second time. Eventually all the balls would get around the bend but the paths of each individual ball would be a chaotic series of crashes and zig-zags.

If we could see the paths of water molecules, as they eventually got round the bend, they would be equally chaotic. Water cannot flow round a bend or a corner, it sort of clatters and crashes its way round in a process known as turbulence and this is another loss to consider when designing pipe-work systems. Although, as described earlier, this reduction in flow due to turbulence is more like a multi car pile-up than a loss purely due to friction, it is easier to think of each bend or elbow as if it

|

Water cannot “flow”

around a bend or

corner - it sort of

clatters and crashes

its way round.....

|

|

were equivalent to a straight, but longer, length of pipe that would cause the same amount of friction as the elbow. That way, all the fittings can have these equivalent lengths added up as if they were one long continuous straight piece and this (imaginary) length can be added to the total length of all the genuinely straight pieces of pipe. Calculating friction loss then becomes much easier. Instead of having to work out what is happening at every point in the system, it would simply be a case of working out what would happen in a longer but straight piece of pipe. Calculating friction losses in pipe-work is the subject of a separate article and, as such, is beyond the scope of this introduction to how and why these losses occur, other than to say the losses reduce as pipe sizes increase. And plumbing fittings, where the water changes direction, add to the losses, with the sharper bends causing more loss than gentle or radiused ones.

Allowing for friction loss in the design

As far as friction loss is concerned, water doesn’t care whether it is being pushed by a pump or pulled by gravity as it travels along pipe-work, it still experiences friction losses. The best way to reduce them is to increase the diameter of the pipe and plan the layout of the equipment so as to keep pipe runs as short as possible with the minimum number of fittings that are necessary. Bear in mind also that a pump which the manufacturer claims will pump, say, 10,000 litres per hour, will only do this in the simplest of plumbing systems where friction losses are almost eliminated. After reducing friction losses as far as is possible by good design, the way to achieve a particular flow rate in a pumped system, is to make sure that the pump size is correct for the total friction losses in the system, and the article on calculating them [to be published on here soon] tells you how to do that.

There is one point that I rarely see taken into account in plumbing design and this is a little trick that was passed on to me by a pump manufacturer. When they are testing new pumps, manufacturers obviously want to squeeze every last drop of performance out of it in their test set-up so that the performance curves look just that little bit better. To gain just that little bit extra performance, they make sure that the pipe-work in front of the pump is straight and has no fittings for at least 20 times the inside diameter of the pipe work feeding the pump suction (input). This means that if the pipe-work leading to the pump is 1½ inch, which has an internal diameter of 1.7 inches, the pipe-work should be straight and have no fittings at all for 34 inches (1.7 x 20). This only makes a small percentage difference in terms of litres per hour but it is such a simple thing to do that it is a practice I would always recommend wherever there is sufficient space in front of the pump because with a pump running 24 hours a day, the increase in performance is significant and it helps to counteract friction losses.

|

|

< Back to index

|

|

|

|

|